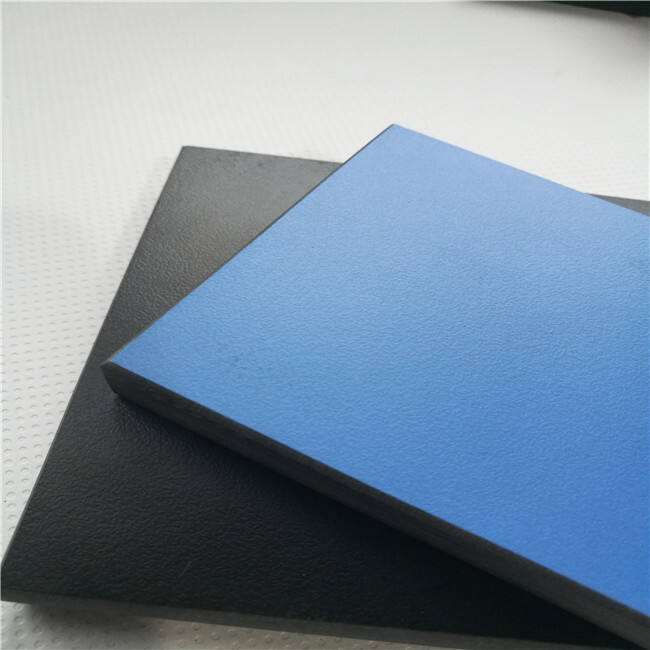

compact phenolic board

Compact phenolic board represents a cutting-edge advancement in construction and interior design materials, combining durability with sophisticated aesthetics. This high-pressure laminate material consists of multiple layers of kraft paper impregnated with phenolic resin, topped with decorative paper and a protective melamine surface. The manufacturing process involves subjecting these layers to high pressure and temperature, resulting in a dense, uniform panel that exhibits exceptional strength and resistance properties. The board's composition ensures superior moisture resistance, making it particularly suitable for wet environments. Its non-porous surface prevents bacterial growth and simplifies maintenance procedures, while its chemical-resistant properties make it ideal for laboratory and healthcare settings. The versatility of compact phenolic board extends to various applications, including wall cladding, bathroom partitions, laboratory furniture, and architectural facades. The material's structural integrity allows for both interior and exterior applications, maintaining its appearance and performance under diverse environmental conditions. Modern manufacturing techniques enable the production of boards in various thicknesses, typically ranging from 2mm to 20mm, with custom color options and surface finishes to meet specific design requirements.