Understanding the Weather-Resistant Properties of High-Pressure Laminate Cladding

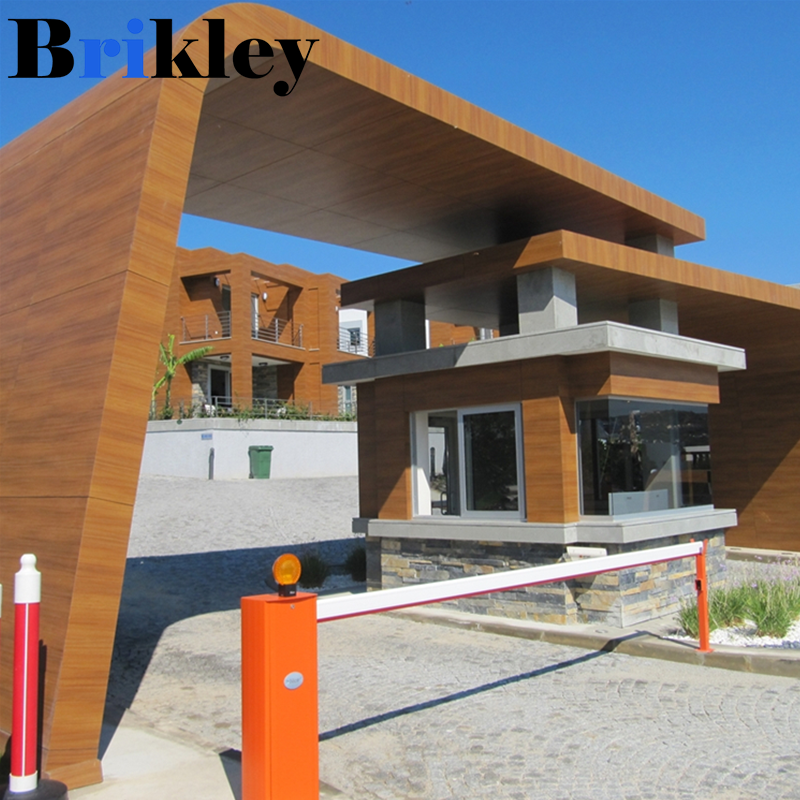

When it comes to protecting buildings from nature's harshest elements, HPL exterior panels have emerged as a leading solution in modern architecture and construction. These innovative cladding materials combine durability with aesthetic appeal, making them increasingly popular for both commercial and residential applications. Their exceptional performance in challenging weather conditions has made them a preferred choice for architects and builders worldwide.

The remarkable resilience of HPL exterior panels stems from their unique manufacturing process, where multiple layers of kraft paper are saturated with thermosetting resins and subjected to high pressure and temperature. This creates an incredibly dense, non-porous material that stands up to whatever Mother Nature throws at it.

Core Components and Manufacturing Excellence

Advanced Material Composition

HPL exterior panels are engineered with precision, featuring multiple layers that work together to create an exceptionally durable product. The core consists of kraft paper layers impregnated with phenolic resins, while the surface layer incorporates decorative paper treated with melamine resins. This combination results in panels that are not only aesthetically pleasing but also incredibly resistant to environmental stressors.

The manufacturing process involves subjecting these layers to pressures exceeding 1,400 psi and temperatures above 280°F. This creates a homogeneous panel with superior structural integrity and remarkable weather resistance properties that far exceed traditional cladding materials.

Quality Control and Testing Standards

Every batch of HPL exterior panels undergoes rigorous testing to ensure consistent performance in extreme conditions. Manufacturers employ various standardized tests, including exposure to UV radiation, temperature cycling, and moisture resistance evaluations. These quality control measures guarantee that the panels maintain their structural integrity and appearance throughout their service life.

The testing protocols often exceed industry standards, subjecting panels to conditions more severe than they would typically encounter in real-world applications. This thorough approach ensures that when installed on buildings, these panels will perform reliably for decades.

Performance in Various Weather Conditions

Heat and UV Resistance

In regions with intense solar exposure, HPL exterior panels demonstrate exceptional stability. The specially formulated surface layer contains UV-resistant properties that prevent color fading and material degradation. Even in temperatures exceeding 180°F, these panels maintain their structural integrity without warping or delamination.

The panels' thermal stability is particularly impressive, as they experience minimal expansion and contraction compared to other cladding materials. This characteristic helps maintain the building's appearance and prevents gaps or misalignment in the façade system over time.

Cold Weather Durability

When temperatures plummet, HPL exterior panels continue to perform admirably. Their dense composition prevents moisture absorption that could lead to freezing damage, while their flexibility allows them to withstand the stress of thermal cycling without cracking or becoming brittle.

Even in areas with frequent freeze-thaw cycles, these panels maintain their structural integrity and appearance. The material's resistance to moisture penetration is crucial in preventing the internal degradation that often affects other cladding materials in cold climates.

Moisture and Storm Protection

Rain and Humidity Management

One of the most impressive features of HPL exterior panels is their exceptional moisture resistance. The non-porous nature of the material prevents water absorption, while the panel system's design includes ventilation gaps that promote proper drainage and air circulation. This combination effectively protects the building envelope from water damage and prevents the growth of mold and mildew.

In high-humidity environments, these panels maintain their dimensional stability and appearance without swelling or warping. The material's impermeability to moisture makes it an ideal choice for coastal regions and areas with high annual rainfall.

Wind and Impact Resistance

HPL exterior panels are engineered to withstand significant wind loads and impact from wind-borne debris. When properly installed, they can resist wind speeds exceeding 100 mph without compromising their attachment to the building structure. This makes them particularly suitable for hurricane-prone regions and high-rise buildings exposed to strong winds.

The panels' impact resistance also provides protection against hail and other forms of precipitation that might damage less durable cladding materials. Their robust construction helps maintain the building's protective envelope even under severe weather conditions.

Long-Term Performance and Maintenance

Durability and Lifespan

When properly installed and maintained, HPL exterior panels typically last 30 years or more. Their color stability and structural integrity remain largely unchanged throughout their service life, making them a cost-effective choice for building owners. The panels resist scratching, impact damage, and chemical exposure, maintaining their appearance with minimal intervention.

The long-term performance of these panels is particularly impressive when considering their exposure to varying weather conditions throughout the seasons. Their resistance to environmental stressors contributes to reduced maintenance requirements and lower lifecycle costs.

Maintenance Requirements

The maintenance needs of HPL exterior panels are remarkably minimal. Regular cleaning with mild soap and water is typically sufficient to maintain their appearance. The non-porous surface prevents the accumulation of dirt and biological growth, while also resisting graffiti and other forms of vandalism.

Annual inspections of the panel system, focusing on joints and attachments, help ensure optimal performance and identify any potential issues before they become significant problems. This proactive approach to maintenance helps extend the system's service life while preserving its aesthetic appeal.

Frequently Asked Questions

Can HPL exterior panels withstand severe temperature fluctuations?

Yes, HPL exterior panels are specifically engineered to handle extreme temperature variations. Their unique composition allows them to maintain stability and structural integrity in temperatures ranging from -60°F to 180°F, making them suitable for diverse climate zones.

How do HPL panels compare to traditional cladding materials in storms?

HPL exterior panels often outperform traditional cladding materials during severe weather events. Their high impact resistance, wind load capacity, and moisture resistance make them particularly effective in protecting buildings during storms, while their lightweight nature reduces structural stress.

What is the expected lifespan of HPL exterior panels in harsh environments?

In harsh environments, properly installed HPL exterior panels typically maintain their performance characteristics for 30 years or more. Their durability, UV resistance, and minimal maintenance requirements contribute to their long-term value and reliability as a cladding solution.