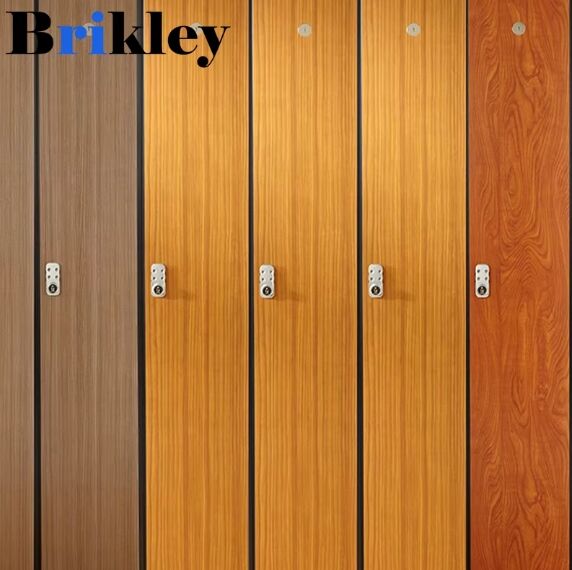

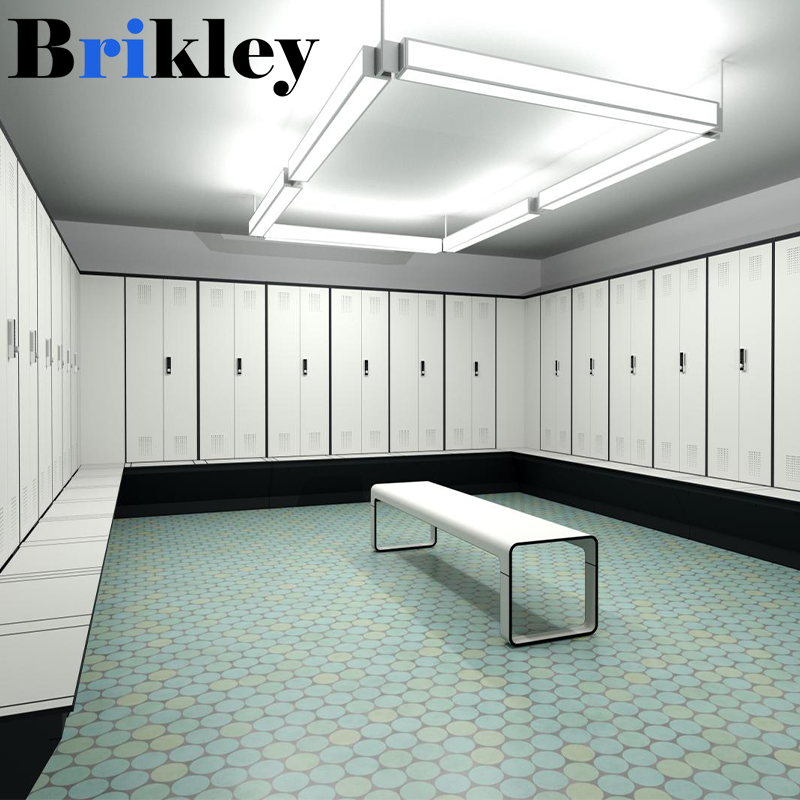

high pressure laminate phenolic board

High pressure laminate phenolic board is an advanced composite material engineered for exceptional durability and performance in demanding environments. This innovative product combines multiple layers of kraft paper impregnated with phenolic resin, which are then compressed under high pressure and temperature to create a dense, stable board. The manufacturing process results in a material that exhibits remarkable strength, moisture resistance, and chemical stability. These boards feature a decorative surface layer that can mimic various materials while maintaining superior scratch and wear resistance. The core structure provides dimensional stability and excellent mechanical properties, making it ideal for both interior and exterior applications. The boards are available in various thicknesses and sizes, offering versatility in design and implementation. They meet strict industry standards for fire resistance, hygiene, and environmental safety, making them suitable for use in commercial, industrial, and institutional settings. The phenolic core ensures exceptional resistance to bacterial growth and makes the boards easy to clean and maintain, while their lightweight nature facilitates easy installation and handling.