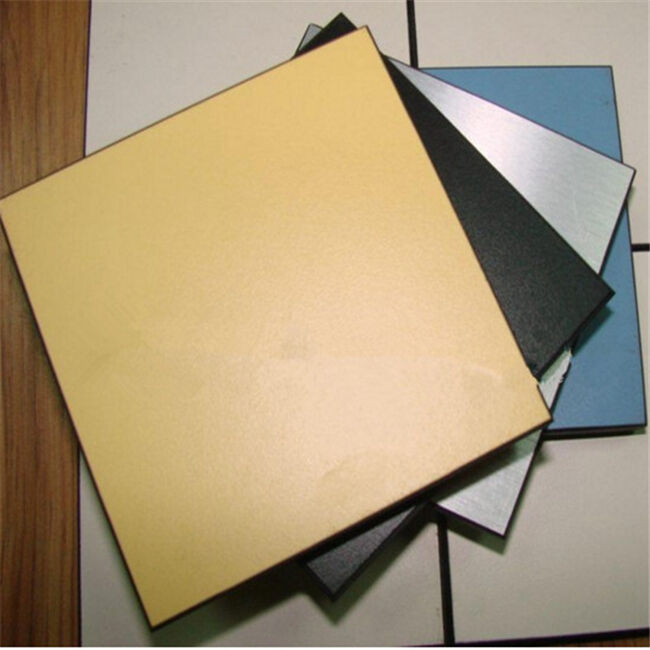

laminated phenolic board

Laminated phenolic board is a high-performance composite material engineered from layers of phenolic resin-impregnated kraft paper, compressed and cured under high pressure and temperature. This advanced manufacturing process creates a versatile material that combines exceptional strength, durability, and chemical resistance. The board features a distinctive layered structure that contributes to its superior mechanical properties, including high compressive strength and dimensional stability. It excels in environments where traditional materials might fail, offering remarkable resistance to moisture, chemicals, and extreme temperatures. The material's versatility makes it ideal for various industrial applications, from electrical insulation to structural components. Its non-conductive properties and flame-resistant characteristics make it particularly valuable in electrical and electronic applications. The board's surface can be customized with different finishes and colors, while maintaining its core performance characteristics. In industrial settings, it serves as a reliable solution for high-stress applications, including machine parts, industrial workbenches, and chemical processing equipment. The material's ability to maintain its properties under challenging conditions, combined with its excellent machinability, makes it a preferred choice for precision engineering applications.