phenolic resin countertop manufacturers

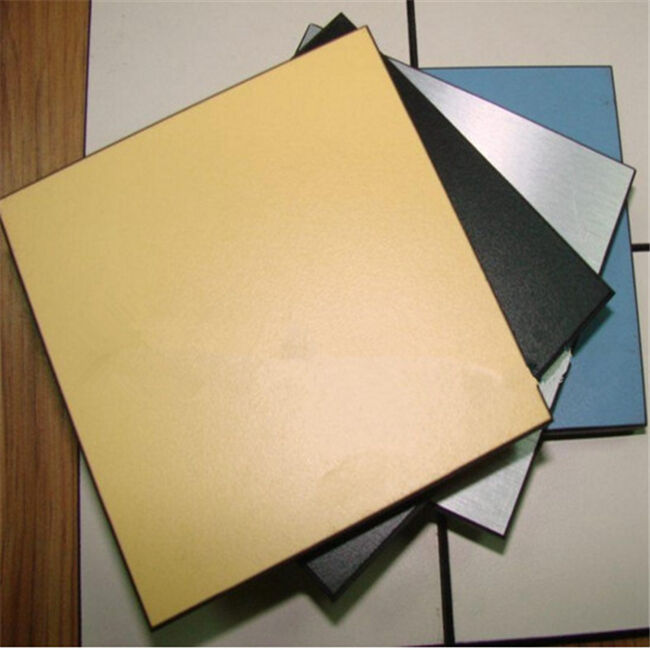

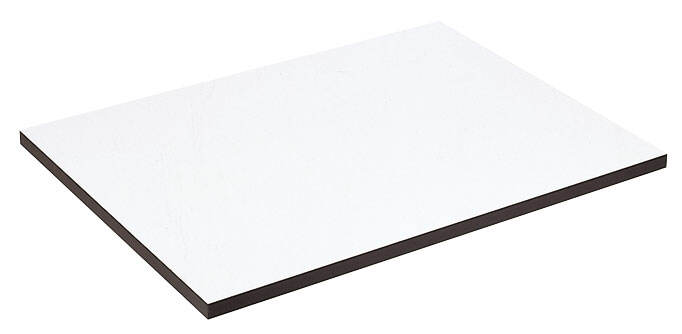

Phenolic resin countertop manufacturers are industry leaders specializing in the production of high-performance, durable laboratory and institutional surfaces. These manufacturers combine advanced manufacturing techniques with superior raw materials to create countertops that meet stringent quality standards. Their production processes involve the careful layering of kraft paper or fabric materials impregnated with phenolic resins, which are then subjected to high pressure and temperature to create a dense, non-porous surface. These manufacturers utilize state-of-the-art equipment and quality control measures to ensure consistent product quality. They typically offer customization options, including various thicknesses, colors, and edge treatments to meet specific project requirements. The manufacturing facilities are equipped with modern cutting and finishing equipment, enabling precise dimensioning and edge profiling. Many manufacturers also provide comprehensive support services, including technical consultation, installation guidance, and after-sales support. Their products find extensive applications in research laboratories, educational institutions, healthcare facilities, and industrial settings where chemical resistance and durability are paramount.