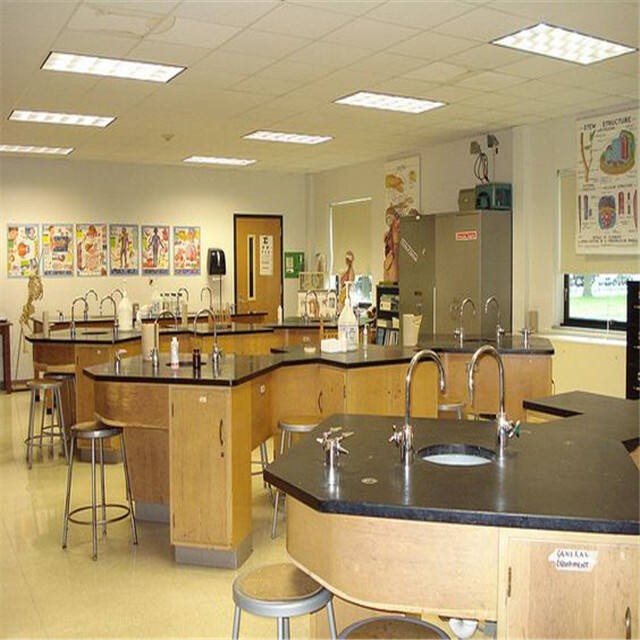

phenolic countertop manufacturer

A phenolic countertop manufacturer specializes in producing high-performance, laboratory-grade surfaces that combine durability with chemical resistance. These manufacturers utilize advanced compression molding technology to create countertops from phenolic resin, a thermosetting plastic material reinforced with cellulose paper. The manufacturing process involves precisely layering phenolic-saturated kraft paper under extreme heat and pressure, resulting in a solid, non-porous surface that's ideal for demanding environments. Modern phenolic countertop manufacturers employ sophisticated quality control systems and automated production lines to ensure consistent product quality. They typically offer customization options, including various thicknesses, colors, and edge profiles to meet specific application requirements. The manufacturing facilities are equipped with state-of-the-art CNC machines for precise cutting and finishing, ensuring exact dimensions and smooth edges. These manufacturers also maintain strict environmental controls during production to prevent contamination and ensure the final product meets laboratory and industrial standards. Their capabilities often extend to providing complete solutions, including custom fabrication, installation support, and technical consultation for optimal product application.