Բարձր ճնշման տախտակապատման կլինինգի եղանակային դիմադրության հասկացությունը

Ճարտարապետական դիզայնը մշտական մարտահրավերների առջև է կանգնած Բնության կողմից, ինչը շենքերի երկարակեցության համար արտաքին նյութերի ընտրությունը կարևոր դարձնում: HPL արտաքին սալիկները դարձել են առաջատար լուծումը խիստ եղանակային պայմաններին ենթարկվող շենքերի համար՝ առաջարկելով տևականություն, էսթետիկա և նշանակալի եղանակային դիմադրություն: Այս նորարարական փողկապման նյութերը փոխակերպել են մեր մոտեցումը շենքերի պաշտպանությանը ծայրահեղ եղանակային գործոններից:

Ժամանակակից շենքերը պահանջում են նյութեր, որոնք կարող են դիմակայել ամեն ինչի՝ սկսած այրող ջերմությունից մինչև սառը ջերմաստիճաններ, իսկ HPL արտաքին սալիկները գերազանց են այդ բարձր պահանջները բավարարելու մեջ: Դրանց եզակի կազմը և արտադրության գործընթացը ստեղծում են ամուր պաշտպանական շերտ, որը պաշտպանում է կառույցները՝ պահպանելով դրանց տեսողական գեղեցկությունը տարիներ շարունակ եղանակային ազդեցությունների դեմ:

Հիմնական բաղադրիչներ և արտադրության գերազանցություն

Նորարար նյութերի կազմություն

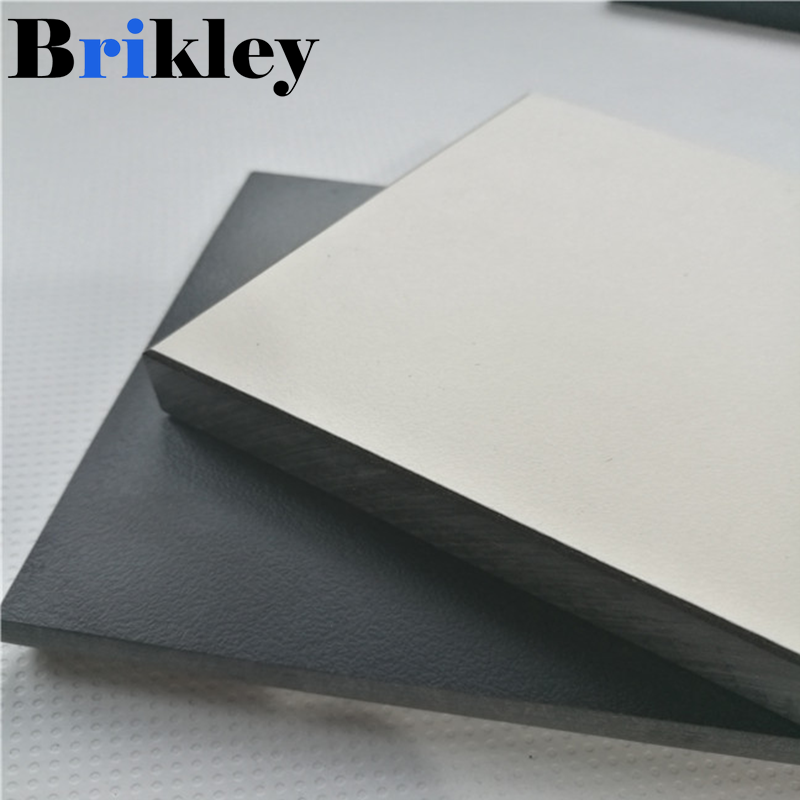

HPL արտաքին վահանակները պատրաստվում են բարդ գործընթացի միջոցով, որը համատեղում է կրաֆտ թղթի, դեկորատիվ թղթի և մասնագիտացված խեժերի բազմաթիվ շերտեր: Այս շերտերը ենթարկվում են ինտենսիվ ճնշման և բարձր ջերմաստիճանի մշակման, ինչի արդյունքում ստացվում են վահանակներ, որոնք ցուցաբերում են բացառիկ ամրություն և եղանակային պայմանների նկատմամբ դիմադրողականություն: Արտադրական գործընթացը ապահովում է, որ յուրաքանչյուր վահանակ պահպանի հաստատուն որակ և աշխատանքային բնութագրեր:

Հիմնական նյութը հզորացված է ջերմակայուն խառնուրդներով, որոնք ստեղծում են խոնավության և շրջակա միջավայրի գործոնների նկատմամբ անթափանց պատնեշ: Այս կազմը նպաստում է սալիկների չափային կայունությանը և կայունությանը թեքվելուց, նույնիսկ երբ ենթարկվում են ջերմաստիճանի կտրուկ փոփոխությունների:

Որակի վերահսկողություն և փորձարկման ստանդարտներ

HPL արտաքին սալիկների յուրաքանչյուր շարք ենթարկվում է խիստ փորձարկումների՝ համապատասխանությունն ապահովելու համար միջազգային շինարարական ստանդարտներին: Արտադրողները սալիկները ենթարկում են արագացված այսության փորձարկումների, որոնք մոդելավորում են տասնյակ տարիների ընթացքում ծայրահեղ պայմանների ազդեցությունը: Այս փորձարկումները գնահատում են UV դիմադրությունը, գույնի կայունությունը, հարվածային դիմադրությունը և կառուցվածքային ամբողջականությունը:

Որակի վերահսկման գործընթացը ներառում է ջերմային շոկի փորձարկում, երբ սալիկները ենթարկվում են ծայրահեղ ջերմաստիճանային տատանումների՝ ստուգելու իրենց կառուցվածքային ամբողջականությունը պահպանելու ունակությունը: Այս համապարփակ փորձարկման ռեժիմը երաշխավորում է, որ տեղադրված սալիկները կաշխատեն հուսալիորեն իրական պայմաններում:

Եղանակային աշխատանքային բնութագրեր

Ջերմաստիճանի դիմադրություն և կայունություն

HPL արտաքին սալիկները ցուցաբերում են հիանալի կայունություն լայն ջերմաստիճանային դիապազոնում՝ -60°C-ից +80°C (-76°F-ից +176°F): Այս արտակարգ ջերմաստիճանային դիմադրությունը կանխում է կորությունը, ծռման առաջացումը կամ դեֆորմացիան, որոնք կարող են վնասել շենքի կեղևը: Սալիկները պահպանում են իրենց չափային կայունությունը կրկնվող սառեցման-հալման ցիկլերի ընթացքում, ինչը դրանք դարձնում է իդեալական տարածաշրջանների համար, որտեղ ներառված են ջերմաստիճանի բարձր տատանումներ:

Նրանց ջերմային դիմադրության հատկությունները նաև նպաստում են շենքի էներգաօգտագործման արդյունավետությանը: Սալիկները օգնում են պահպանել ներքին տարածքների կայուն ջերմաստիճանը՝ ավելացնելով մեկ լրացուցիչ մեկուսացման շերտ, որը նվազեցնում է տաքացման և սառեցման համակարգերի ծանրաբեռնվածությունը:

Լիցքի և խոնավության պաշտպանություն

HPL արտաքին սալիկների ամենացուցադրական հատկանիշներից մեկը նրանց գերիշխող խոնավության դիմադրությունն է: Սալիկների փակ մակերևույթն ու կնքված եզրերը կանխարգելում են ջրի xնկալումը՝ վերացնելով փտման, սունկի աճի կամ ներքին քայքայման վախերը: Խոնավության նկատմամբ դիմադրությունը պահպանվում է նաև այն տարածքներում, որտեղ առատ անձրևներ կամ բարձր խոնավություն է դիտվում:

Սալիկների ջրադիմացկուն հատկությունները տարածվում են նաև նրանց սրտիկի վրա, ապահովելով, որ նույնիսկ մակերևույթին առաջացած փոքր վնասվածքների դեպքում ներքին կառուցվածքը պաշտպանված մնա: Խոնավության նկատմամբ այս համապարփակ պաշտպանությունը զգալիորեն երկարաձգում է շենքի շրջանակի կյանքի տևողությունը:

Շրջակա միջավայրի ազդեցության դիմադրություն

ՈՒՖ և արևային ճառագայթման դիմադրություն

HPL արտաքին սալիկները ներառում են առաջադեմ UV պաշտպանության տեխնոլոգիաներ, որոնք կանխում են գույնի արտահոսքը և նյութի վատթարացումը։ Սալիկների մակերեսի մշակումը ներառում է հատուկ միացություններ, որոնք արտացոլում են վնասակար ՈՒՖ ճառագայթները՝ պահպանելով գույնի կայունությունը։ Այս պաշտպանությունը երաշխավորում է, որ շենքերը պահպանում են իրենց էսթետիկ գրավչությունը տասնամյակներ շարունակ, նույնիսկ այն տեղանքներում, որտեղ առկա է ինտենսիվ արևային ազդեցություն։

ՈՒՖ-ին դիմադրող հատկությունները մակերեսային չեն, այլ ամբողջական կերպով ներառված են սալիկի կազմության մեջ։ Այս համապարփակ պաշտպանությունը նշանակում է, որ նույնիսկ եթե մակերեսը մաշվի, հիմքի նյութը շարունակում է արդյունավետորեն դիմադրել արևի ազդեցությանը։

Քամու և հարվածային պաշտպանություն

Բարձր հողմերը և թռչող մասերը ներկայացնում են խիստ մակերեսային պատնեշների համար։ HPL արտաքին սալիկները ցուցադրում են բացառիկ հարվածային դիմադրություն, պաշտպանելով շենքերը փոթորիկի ժամանակ հողմով տեղափոխվող օբյեկտներից։ Դրանց ամուր կառուցվածքը և ճիշտ տեղադրման համակարգերը թույլ են տալիս դիմակայել բարձր քամու բեռներին՝ առանց կորցնելու կառուցվածքային ամբողջականությունը։

Սալիկների ամրության և զանգվածի հարաբերակցությունը օպտիմալացնում է դրանց աշխատանքը ծայրահեղ քամու պայմաններում։ Դրանց համեմատաբար փոքր զանգվածը՝ համակցված բարձր կառուցվածքային ամրության հետ, նվազեցնում է շենքի կառուցվածքի բեռը՝ պահպանելով գերազանց պաշտպանությունը շրջակա միջավայրի ազդեցություններից։

Երկարաժամկետ աշխատանք և սպասարկում

Տևողականություն և սպասվող կյանք

Ճիշտ տեղադրման և սպասարկման դեպքում HPL արտաքին սալիկները, որպես կանոն, ծառայում են ավելի քան 30 տարի: Այս հպարտանք հարուցող երկարակեցությունը պայմանավորված է դրանց դիմադրությամբ և ներքին նյութերի որակով: Սալիկները պահպանում են իրենց կառուցվածքային ամբողջականությունը և տեսքը ամբողջ ծառայողական կյանքի ընթացքում՝ ապահովելով գերազանց վերադարձ շենքերի սեփականատերերի ներդրումներին:

Այս սալիկների տևականությունը չի սահմանափակվում միայն եղանակային դիմադրությամբ, այլ նաև ներառում է դիմադրություն քիմիական նյութերի, աղտոտվածության և այլ շրջակա միջավայրի աղտոտիչների նկատմամբ, որոնք կարող են վնասել արտաքին մակերեսները:

Պահպանման պահանջներ և ընթադարձություններ

HPL արտաքին սալիկների ամենագրավիչ հատկանիշներից մեկը նրանց նվազագույն սպասարկման պահանջն է: Նրանց տեսքն ու կատարողականությունը պահպանելու համար, որպես կանոն, բավարար է սովորական օճառով և ջրով կատարվող պարբերական մաքրում: Չներծծող մակերեսը խոչընդոտում է փոշու և կեղտի խորը նստելուն, ինչը պահպանման ընթադարձությունները դարձնում է պարզ և տնտեսապես շահավետ:

Խորհուրդ է տրվում տարեկան զննումներ իրականացնել՝ ստուգելու ամրացման համակարգերի կամ կնիքերի հնարավոր խնդիրները, սակայն սարքերի ինքնուրույն նշանակալի սպասարկման հազվադեպ կարիք կա. Այս ցածր սպասարկման բնույթը նպաստում է ցածր երկարաժամկետ սեփականության ծախսերի։

Հաճախ տրվող հարցեր

Ի՞նչ է տարբերում HPL արտաքին սալիկները ավանդական պատնեշային նյութերից։

HPL արտաքին սալիկները ավանդական նյութերի համեմատ առաջարկում են գերազանց եղանակային դիմադրություն, տևողականություն և էսթետիկ բազմազանություն: Դրանց ինժեներական կազմը ավելի լավ պաշտպանություն է ապահովում ՈՒՖ ճառագայթներից, խոնավությունից և ջերմաստիճանի տատանումներից՝ նվազագույն սպասարկման կարիք ունենալով:

Որքա՞ն ժամանակ կարող են HPL արտաքին սալիկները պահպանել իրենց տեսքը խիստ արևային լույսի պայմաններում:

Ճիշտ տեղադրման և նվազագույն սպասարկման դեպքում HPL արտաքին սալիկները կարող են պահպանել իրենց գույնն ու տեսքը 20-30 տարի, նույնիսկ այն տարածքներում, որտեղ արևի ազդեցությունը շատ ուժեղ է: Դրանց ինտեգրված ՈՒՖ պաշտպանությունը կանխում է նշանակալի թուլացումն ու վատթարացումը:

Համապատասխանո՞ւմ են արդյոք HPL արտաքին սալիկները ծովափնյա շրջակա միջավայրին

Այո՛, HPL արտաքին սալիկները հիանալի են աշխատում ծովափնյա շրջակա միջավայրում: Նրանց դիմադրությունը աղի ցանկապատերին, խոնավությանը և ուժեղ քամիներին դարձնում է սալիկներին իդեալական ծովափնյա շենքերի համար: Սալիկների ոչ կոռոզիոն բնույթը երաշխավորում է երկարաժամկետ տևողություն այս բարդ պայմաններում:

Ո՞ր ջերմաստիճանային սահմաններում են դիմացկուն HPL արտաքին սալիկները

HPL արտաքին սալիկները նախագծված են աշխատելու -60°C-ից +80°C (-76°F-ից +176°F) ջերմաստիճանների սահմաններում: Նրանք պահպանում են իրենց կառուցվածքային ամրությունն ու տեսքը՝ բազմաթիվ կրկնվող սառեցման-հալման ցիկլերի և ջերմաստիճանի սրածայր փոփոխությունների դեմ դիմադրելով:

Բովանդակության աղյուսակ

- Բարձր ճնշման տախտակապատման կլինինգի եղանակային դիմադրության հասկացությունը

- Հիմնական բաղադրիչներ և արտադրության գերազանցություն

- Եղանակային աշխատանքային բնութագրեր

- Շրջակա միջավայրի ազդեցության դիմադրություն

- Երկարաժամկետ աշխատանք և սպասարկում

-

Հաճախ տրվող հարցեր

- Ի՞նչ է տարբերում HPL արտաքին սալիկները ավանդական պատնեշային նյութերից։

- Որքա՞ն ժամանակ կարող են HPL արտաքին սալիկները պահպանել իրենց տեսքը խիստ արևային լույսի պայմաններում:

- Համապատասխանո՞ւմ են արդյոք HPL արտաքին սալիկները ծովափնյա շրջակա միջավայրին

- Ո՞ր ջերմաստիճանային սահմաններում են դիմացկուն HPL արտաքին սալիկները