Industrial environments demand materials that can withstand harsh conditions while maintaining structural integrity and performance over extended periods. Among the most versatile and reliable solutions available today is phenolic resin board, a high-performance composite material engineered specifically for demanding applications. This advanced material combines exceptional durability with chemical resistance, making it an ideal choice for laboratories, manufacturing facilities, and other industrial settings where conventional materials often fail to meet rigorous requirements.

The growing adoption of phenolic resin board across various industries reflects its superior properties and cost-effectiveness compared to traditional materials. From pharmaceutical research facilities to food processing plants, this innovative material continues to prove its worth in applications where safety, hygiene, and longevity are paramount. Understanding the specific advantages and applications of phenolic resin board enables decision-makers to make informed choices that enhance operational efficiency while reducing long-term maintenance costs.

Chemical Resistance and Durability Properties

Superior Chemical Resistance Characteristics

One of the most significant advantages of phenolic resin board lies in its exceptional resistance to a wide range of chemicals commonly found in industrial environments. The molecular structure of phenolic resins creates a dense, cross-linked network that effectively prevents chemical penetration and degradation. This resistance extends to acids, bases, solvents, and various organic compounds, making it suitable for applications where exposure to corrosive substances is routine.

Laboratory environments particularly benefit from this chemical resistance, as researchers frequently work with aggressive chemicals that can quickly deteriorate standard materials. The non-porous surface of phenolic resin board prevents absorption of spilled chemicals, reducing the risk of contamination and ensuring easy cleanup. This characteristic also contributes to maintaining sterile conditions, which is crucial in pharmaceutical and biotechnology applications where even minor contamination can compromise research results or product quality.

Long-Term Structural Integrity

The durability of phenolic resin board extends far beyond its chemical resistance properties. The material exhibits excellent dimensional stability under varying temperature and humidity conditions, maintaining its shape and structural properties even in challenging environments. This stability prevents warping, cracking, or delamination that commonly affects other composite materials over time, ensuring consistent performance throughout the material's service life.

Impact resistance is another critical durability factor where phenolic resin board excels. The material can withstand significant mechanical stress without cracking or chipping, making it suitable for high-traffic areas and applications involving heavy equipment. This robustness translates to reduced maintenance requirements and lower replacement costs, providing excellent long-term value for industrial facilities seeking reliable material solutions.

Thermal and Fire Safety Properties

Heat Resistance and Temperature Stability

Industrial processes often involve elevated temperatures that can compromise the integrity of conventional materials. Phenolic resin board demonstrates remarkable thermal stability, maintaining its mechanical properties across a wide temperature range. The material can typically withstand continuous exposure to temperatures up to 150°C without significant degradation, making it suitable for applications near heat sources or in thermally demanding environments.

The low thermal conductivity of phenolic resin board also provides insulation benefits, helping to maintain stable surface temperatures even when exposed to heat sources. This property is particularly valuable in laboratory settings where temperature-sensitive experiments require stable environmental conditions. Additionally, the material's resistance to thermal shock prevents cracking or failure when subjected to rapid temperature changes, ensuring reliable performance in dynamic industrial environments.

Fire Safety and Smoke Generation

Fire safety is a critical consideration in industrial settings, and phenolic resin board offers superior performance compared to many alternative materials. The inherent flame-retardant properties of phenolic resins result in low flame spread rates and reduced smoke generation during combustion. This characteristic is particularly important in enclosed spaces where smoke accumulation could pose serious safety risks to personnel.

The material typically achieves high ratings in standardized fire safety tests, including low smoke toxicity levels that enhance evacuation safety during emergency situations. Many phenolic resin board products meet stringent building code requirements for fire-rated applications, making them suitable for use in facilities where fire safety regulations are particularly demanding. This compliance reduces regulatory concerns while providing enhanced protection for both personnel and equipment.

Hygiene and Maintenance Benefits

Non-Porous Surface Properties

The non-porous surface of phenolic resin board provides significant hygiene advantages in industrial applications where cleanliness is essential. Unlike porous materials that can harbor bacteria, mold, or other contaminants, the smooth, sealed surface prevents microbial growth and simplifies sanitization procedures. This characteristic is particularly valuable in pharmaceutical manufacturing, food processing, and healthcare facilities where maintaining sterile conditions is mandatory.

The surface's resistance to staining ensures that spilled substances do not permanently discolor or damage the material, maintaining aesthetic appeal and professional appearance over time. This stain resistance also contributes to easier identification of contamination, as foreign substances remain visible on the surface rather than being absorbed into the material. Such visibility enables prompt cleaning and helps maintain the high standards of cleanliness required in sensitive industrial environments.

Simplified Cleaning and Maintenance

Maintenance requirements for phenolic resin board are significantly lower compared to traditional materials, resulting in reduced operational costs and downtime. The smooth surface can be effectively cleaned using standard industrial cleaning agents without risk of surface damage or degradation. This compatibility with various cleaning chemicals allows facilities to maintain their existing sanitization protocols while benefiting from improved material performance.

The material's resistance to wear and abrasion means that frequent cleaning does not cause surface deterioration, maintaining the integrity of the protective barrier over extended periods. This durability reduces the need for surface refinishing or replacement, minimizing maintenance-related disruptions to industrial operations. Additionally, the material does not require special treatments or coatings to maintain its performance characteristics, further simplifying maintenance procedures.

Versatile Industrial Applications

Laboratory and Research Environments

Laboratory applications represent one of the primary markets for phenolic resin board due to its exceptional combination of chemical resistance, durability, and hygiene properties. Research facilities utilize this material for laboratory benches, fume hood work surfaces, and chemical storage areas where exposure to aggressive substances is common. The material's ability to withstand acids, bases, and organic solvents without degradation ensures that laboratory operations can proceed safely and efficiently.

In analytical laboratories, the non-reactive nature of phenolic resin board prevents interference with sensitive testing procedures. The material does not leach chemicals or contribute contaminants that could affect test results, making it ideal for quality control applications where accuracy is paramount. Furthermore, the ease of decontamination between different procedures helps prevent cross-contamination, supporting the integrity of research and testing protocols.

Manufacturing and Processing Facilities

Manufacturing environments benefit from phenolic resin board's durability and chemical resistance in applications ranging from production line surfaces to equipment housing. The material's ability to withstand industrial cleaning chemicals and harsh operating conditions makes it suitable for food processing facilities where sanitization requirements are stringent. Its non-porous surface prevents accumulation of food particles or bacteria, supporting compliance with food safety regulations.

Chemical processing facilities also utilize phenolic resin board for applications where exposure to process chemicals is inevitable. The material's resistance to a broad spectrum of industrial chemicals ensures long-term performance without degradation or safety concerns. This reliability is particularly important in continuous processing operations where material failure could result in costly downtime or safety incidents.

Cost-Effectiveness and Long-Term Value

Initial Investment Versus Lifecycle Costs

While the initial cost of phenolic resin board may be higher than some conventional materials, the long-term economic benefits often justify the investment. The extended service life of this material, typically measured in decades rather than years, significantly reduces replacement costs over time. Additionally, the minimal maintenance requirements translate to lower ongoing operational expenses, improving the overall return on investment for industrial facilities.

The material's resistance to damage from chemicals, impact, and thermal stress prevents premature failure that commonly affects other materials in similar applications. This reliability reduces the risk of unexpected replacement costs and associated downtime, which can be particularly expensive in production environments. Facilities that choose phenolic resin board often experience improved operational continuity and reduced maintenance-related disruptions.

Operational Efficiency Benefits

The performance characteristics of phenolic resin board contribute to improved operational efficiency in various ways. The ease of cleaning and sanitization reduces the time required for maintenance procedures, allowing facilities to maintain higher uptime rates. In laboratory environments, this efficiency translates to more time available for productive research activities rather than surface maintenance and replacement.

The material's consistency and reliability also support quality assurance programs by providing stable, predictable performance characteristics. This predictability is particularly valuable in regulated industries where documentation and validation of material properties are required. The long service life and stable performance of phenolic resin board reduce the frequency of requalification procedures that may be necessary when materials are replaced or upgraded.

FAQ

What makes phenolic resin board different from other composite materials

Phenolic resin board differs from other composite materials primarily through its unique resin chemistry and manufacturing process. The phenolic resin matrix creates a highly cross-linked structure that provides superior chemical resistance and thermal stability compared to materials based on other resin systems. The manufacturing process, which typically involves high-pressure compression molding, results in a dense, non-porous material with excellent mechanical properties and dimensional stability.

How long does phenolic resin board typically last in industrial applications

The service life of phenolic resin board in industrial applications typically ranges from 15 to 25 years, depending on the specific environmental conditions and usage patterns. In laboratory environments with proper maintenance, the material often exceeds these expectations, with some installations remaining functional for over 30 years. The key factors affecting longevity include the severity of chemical exposure, frequency of cleaning, and mechanical stress levels experienced during normal operations.

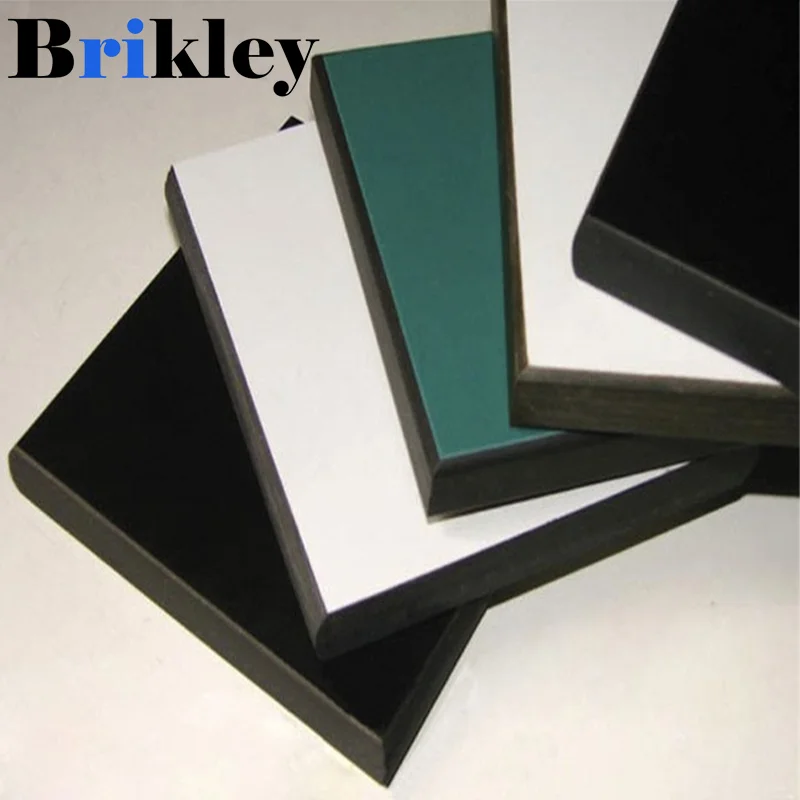

Can phenolic resin board be customized for specific industrial requirements

Yes, phenolic resin board can be manufactured with various specifications to meet specific industrial requirements. Customization options include different thicknesses, surface textures, colors, and enhanced properties such as increased chemical resistance or electrical conductivity. Manufacturers can also incorporate specific additives to improve particular characteristics, such as UV resistance for outdoor applications or enhanced fire retardancy for specialized safety requirements.

What safety considerations should be observed when working with phenolic resin board

Safety considerations for phenolic resin board primarily relate to proper handling during installation and machining operations. Standard personal protective equipment, including safety glasses and dust masks, should be used when cutting or drilling the material to prevent inhalation of dust particles. The material itself is non-toxic and safe for contact with food and pharmaceutical products when properly manufactured, but proper ventilation should be maintained during any fabrication activities to ensure worker safety.

Table of Contents

- Chemical Resistance and Durability Properties

- Thermal and Fire Safety Properties

- Hygiene and Maintenance Benefits

- Versatile Industrial Applications

- Cost-Effectiveness and Long-Term Value

-

FAQ

- What makes phenolic resin board different from other composite materials

- How long does phenolic resin board typically last in industrial applications

- Can phenolic resin board be customized for specific industrial requirements

- What safety considerations should be observed when working with phenolic resin board