Phenolic resin boards represent a pinnacle of engineered materials in laboratory and industrial applications, offering exceptional durability and chemical resistance that makes them indispensable for demanding environments. These composite materials, formed through the compression of phenolic resin-impregnated kraft paper layers under high temperature and pressure, deliver unmatched performance characteristics that justify their widespread adoption across scientific, medical, and industrial facilities. Understanding proper maintenance protocols ensures these premium surfaces maintain their integrity and functionality throughout their extended service life, maximizing the return on investment while ensuring consistent operational excellence. The strategic implementation of maintenance practices not only preserves the aesthetic appeal of these surfaces but also maintains their critical performance properties that make them essential for specialized applications.

Understanding Phenolic Resin Board Composition and Properties

Material Structure and Manufacturing Process

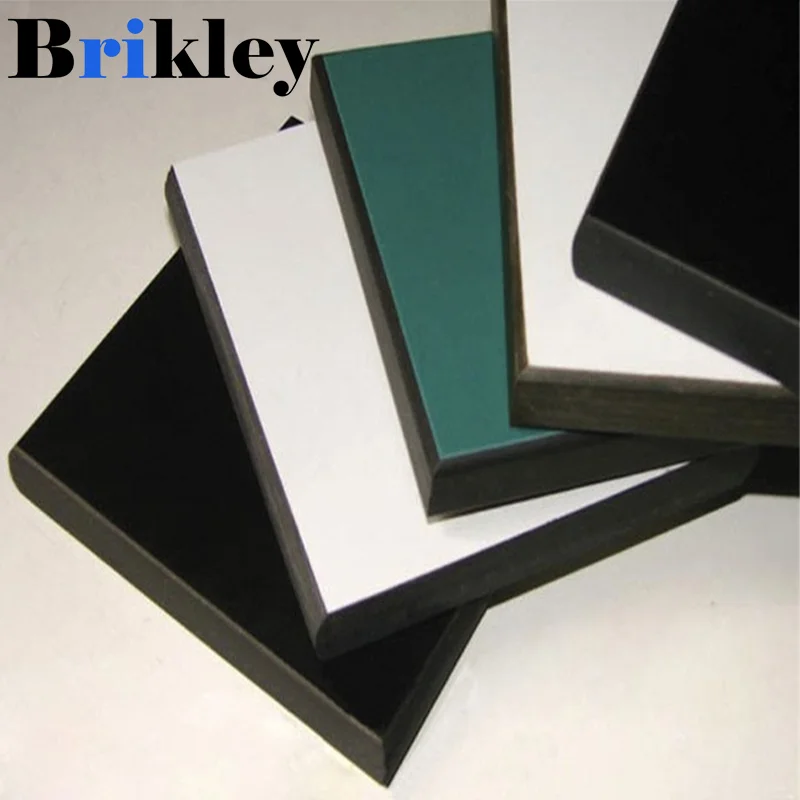

The fundamental structure of phenolic resin board consists of multiple layers of kraft paper saturated with phenolic resin, compressed under extreme heat and pressure to create a dense, homogeneous material. This manufacturing process results in a thermoset plastic composite that exhibits remarkable stability under varying environmental conditions. The cross-linked molecular structure provides inherent resistance to moisture, chemicals, and mechanical stress, making these boards ideal for applications where traditional materials would fail. The manufacturing precision ensures consistent thickness, flatness, and surface quality that meets stringent industry standards for laboratory and industrial use.

The curing process during manufacturing creates irreversible chemical bonds that give phenolic resin board its distinctive properties, including dimensional stability and resistance to delamination. Advanced manufacturing techniques ensure uniform density throughout the material thickness, eliminating weak points that could compromise performance over time. Quality control measures during production verify that each board meets specifications for chemical resistance, mechanical strength, and surface integrity. Understanding these fundamental characteristics helps facility managers develop appropriate maintenance strategies that work with the material's inherent properties rather than against them.

Chemical Resistance and Performance Characteristics

Phenolic resin boards demonstrate exceptional resistance to a wide range of chemicals commonly found in laboratory and industrial environments, including acids, bases, solvents, and organic compounds. This chemical inertness stems from the material's cross-linked polymer structure, which prevents chemical penetration and reaction with the substrate. The non-porous surface finish further enhances chemical resistance by eliminating potential absorption sites where contaminants could accumulate and cause degradation. Regular testing confirms that properly maintained phenolic resin surfaces retain their chemical resistance properties even after years of exposure to aggressive substances.

Temperature stability represents another critical performance characteristic, with high-quality phenolic resin board maintaining structural integrity across a broad temperature range. The material's low thermal expansion coefficient ensures dimensional stability during temperature fluctuations, preventing warping or surface stress that could compromise functionality. Impact resistance and mechanical durability make these boards suitable for heavy-duty applications where other materials would show signs of wear or damage. These performance attributes work synergistically to create surfaces that maintain their appearance and functionality with proper maintenance protocols.

Daily Cleaning and Routine Maintenance Protocols

Recommended Cleaning Solutions and Techniques

Effective daily cleaning of phenolic resin board surfaces requires the use of appropriate cleaning solutions that remove contaminants without compromising the material's integrity or surface finish. Mild detergent solutions mixed with warm water provide excellent general-purpose cleaning capability for routine maintenance, effectively removing organic soils, fingerprints, and light chemical residues. For more challenging contaminants, diluted bleach solutions or specialized laboratory cleaners can be employed, provided they are thoroughly rinsed after application to prevent residue buildup. The key to successful cleaning lies in selecting solutions that match the specific contamination while avoiding harsh abrasives or chemicals that could damage the surface.

Proper cleaning technique involves using soft, non-abrasive cloths or microfiber materials that lift contaminants without scratching the surface. Circular wiping motions should be avoided in favor of straight-line patterns that prevent the formation of visible cleaning marks. Temperature considerations play an important role, as lukewarm cleaning solutions typically provide better cleaning efficiency than cold water while avoiding potential thermal shock to the surface. Immediate removal of spills and prompt cleaning of chemical residues prevents staining and maintains the pristine appearance that characterizes well-maintained phenolic resin board installations.

Frequency and Timing of Maintenance Activities

Establishing appropriate maintenance frequencies ensures that phenolic resin board surfaces receive adequate attention without unnecessary over-cleaning that could waste resources or potentially cause cumulative wear. High-use areas such as laboratory workbenches and preparation surfaces benefit from daily cleaning protocols, while low-traffic areas may require only weekly attention to maintain optimal conditions. The timing of cleaning activities should consider facility operations, with major cleaning tasks scheduled during off-hours to minimize disruption to ongoing work. Documentation of cleaning schedules and activities provides valuable data for optimizing maintenance protocols and identifying areas that may require additional attention.

Environmental factors significantly influence maintenance frequency requirements, with facilities experiencing high dust levels or chemical exposure requiring more frequent attention than controlled laboratory environments. Seasonal variations may also necessitate adjustments to maintenance schedules, particularly in facilities subject to temperature and humidity fluctuations that could affect surface conditions. Monitoring surface conditions through regular inspections helps facility managers identify when maintenance frequencies need adjustment to maintain optimal performance. Proactive scheduling prevents the accumulation of contaminants that become progressively more difficult to remove over time.

Stain Prevention and Removal Strategies

Common Staining Agents and Prevention Methods

Laboratory and industrial environments expose phenolic resin board surfaces to numerous potential staining agents, including organic dyes, metal salts, biological materials, and various chemical compounds that can cause discoloration if not promptly addressed. Prevention strategies focus on minimizing contact time between staining agents and the surface through immediate spill response protocols and the use of protective barriers where appropriate. Understanding the staining mechanisms helps facility personnel recognize high-risk situations and implement preventive measures before discoloration occurs. Regular surface treatment with appropriate sealers or protective coatings can provide additional stain resistance in particularly challenging environments.

Educational programs for facility users play a crucial role in stain prevention, ensuring that personnel understand proper handling techniques for potentially staining materials and the importance of immediate cleanup procedures. Clear protocols for chemical handling and spill response minimize the risk of accidental staining while maintaining operational efficiency. The installation of appropriate drainage systems and containment measures prevents staining agents from spreading across large surface areas, limiting damage to localized areas that can be more easily treated. Preventive maintenance programs should include regular assessment of stain prevention measures and updating of protocols based on operational experience.

Effective Stain Removal Techniques

When stains do occur on phenolic resin board surfaces, prompt action using appropriate removal techniques can often restore the original appearance without permanent damage. The selection of stain removal methods depends on the nature of the staining agent, with organic stains typically responding to different treatments than inorganic or metallic stains. Graduated treatment approaches start with mild cleaning solutions and progress to more aggressive treatments only when necessary, minimizing the risk of surface damage while maximizing stain removal effectiveness. Temperature and contact time considerations are critical, as elevated temperatures can enhance cleaning effectiveness while extended contact times may cause surface degradation.

Mechanical removal techniques, including careful abrasion with fine-grade abrasives, can address stubborn stains that resist chemical treatment. However, these methods require skill and experience to avoid surface damage that could compromise the material's performance characteristics. Professional restoration services may be necessary for severe staining or when standard removal techniques prove ineffective. Documentation of stain removal procedures and their effectiveness provides valuable information for developing standardized protocols and training programs that ensure consistent results across facility maintenance teams.

Long-term Preservation and Performance Optimization

Protective Treatments and Surface Conditioning

Long-term preservation of phenolic resin board performance requires strategic application of protective treatments and surface conditioning procedures that enhance the material's natural resistance properties. Specialized sealers and protective coatings can provide additional chemical resistance and stain protection, particularly in environments with exceptionally aggressive exposure conditions. These treatments must be compatible with the phenolic resin substrate and should not interfere with the material's inherent properties or create maintenance complications. Regular evaluation of protective treatment effectiveness ensures that these measures continue to provide value and do not require premature renewal or replacement.

Surface conditioning procedures, including periodic deep cleaning and reconditioning treatments, help maintain optimal surface characteristics throughout the material's service life. These procedures remove accumulated contaminants that may not be addressed by routine cleaning and restore surface properties that may have been diminished by extended use. Professional assessment of surface conditions guides the selection of appropriate conditioning treatments and their frequency of application. The investment in protective treatments and conditioning procedures typically provides excellent returns through extended service life and maintained performance characteristics.

Environmental Control and Operational Considerations

Maintaining appropriate environmental conditions significantly impacts the long-term performance and appearance of phenolic resin board installations. Temperature and humidity control prevents dimensional changes that could cause stress concentrations or surface irregularities. Adequate ventilation systems remove chemical vapors and contaminants that could accumulate on surfaces and cause gradual degradation over time. Lighting systems should provide adequate illumination for maintenance activities while avoiding excessive heat generation that could affect surface temperatures. These environmental factors work together to create conditions that support optimal material performance and simplified maintenance requirements.

Operational protocols that minimize unnecessary wear and exposure help preserve surface integrity and extend service life. Training programs for facility users ensure proper handling techniques and awareness of factors that could compromise surface performance. Regular facility assessments identify operational changes that may affect maintenance requirements or surface exposure conditions. Integration of maintenance considerations into facility design and operational planning prevents problems before they occur and ensures that maintenance resources are used effectively. Strategic planning for long-term performance optimization provides the foundation for successful phenolic resin board installations that deliver value throughout their intended service life.

Troubleshooting Common Maintenance Challenges

Surface Damage Assessment and Repair Options

Identifying and addressing surface damage promptly prevents minor issues from developing into major problems that could compromise the functionality of phenolic resin board installations. Common types of damage include scratches, chips, chemical etching, and wear patterns that may develop in high-use areas. Systematic assessment procedures help maintenance personnel distinguish between surface-level damage that can be repaired and structural damage that may require replacement. Documentation of damage patterns provides valuable information for improving operational procedures and preventing similar issues in the future.

Repair options for phenolic resin board surfaces range from simple polishing and refinishing procedures to more extensive restoration techniques that can address deeper damage. Surface scratches and minor chemical etching often respond well to careful abrasion and polishing with progressively finer abrasives, followed by appropriate surface treatments to restore protective properties. More severe damage may require professional restoration services that employ specialized equipment and techniques to achieve satisfactory results. Cost-benefit analysis of repair versus replacement helps facility managers make informed decisions about the most appropriate course of action for specific damage situations.

Performance Monitoring and Quality Assurance

Establishing comprehensive performance monitoring programs ensures that phenolic resin board installations continue to meet operational requirements throughout their service life. Regular inspection protocols identify developing issues before they compromise functionality or require expensive corrective measures. Performance metrics should include visual appearance, chemical resistance, mechanical integrity, and dimensional stability measurements that provide objective data about material condition. Trending analysis of performance data helps identify patterns that may indicate needed changes in maintenance protocols or operational procedures.

Quality assurance measures verify that maintenance activities achieve their intended results and do not inadvertently cause damage or degradation. Standardized procedures and training programs ensure consistent maintenance quality across different personnel and facility areas. Regular calibration of testing equipment and validation of assessment procedures maintain the accuracy and reliability of performance monitoring data. Integration of quality assurance principles into maintenance programs provides confidence that phenolic resin board installations will continue to deliver their intended performance benefits throughout their design service life.

FAQ

How often should phenolic resin board surfaces be deep cleaned?

Deep cleaning frequency for phenolic resin board surfaces depends on the specific application environment and exposure conditions, but generally ranges from monthly to quarterly intervals. High-use laboratory environments or areas exposed to aggressive chemicals may require monthly deep cleaning, while office or low-exposure areas can typically maintain optimal conditions with quarterly deep cleaning schedules. The key indicator for deep cleaning necessity is the accumulation of residues or stains that routine daily cleaning cannot effectively remove. Regular assessment of surface conditions helps determine the optimal frequency for each specific installation.

Can phenolic resin board surfaces be refinished if they become severely damaged?

Yes, phenolic resin board surfaces can often be refinished to address moderate to severe damage, though the feasibility depends on the depth and extent of the damage. Surface-level damage such as scratches, light chemical etching, or wear patterns can typically be addressed through progressive abrasion and polishing techniques that remove the damaged layer and restore a smooth finish. However, damage that penetrates deeply into the material structure may require replacement rather than refinishing. Professional assessment is recommended for severe damage to determine whether refinishing can achieve satisfactory results or if replacement would be more cost-effective.

What cleaning products should be avoided on phenolic resin board surfaces?

Certain cleaning products can damage phenolic resin board surfaces and should be avoided to maintain optimal performance and appearance. Highly alkaline cleaners with pH levels above 10 can cause surface etching and discoloration over time. Abrasive cleaners containing harsh scrubbing compounds can create microscopic scratches that compromise surface integrity and provide sites for contamination accumulation. Solvent-based cleaners containing acetone, methyl ethyl ketone, or similar aggressive solvents may soften or dissolve surface layers. Always test new cleaning products in inconspicuous areas before widespread use and consult manufacturer recommendations for approved cleaning solutions.

How can I tell if my phenolic resin board maintenance program is effective?

An effective maintenance program for phenolic resin board surfaces demonstrates measurable results through several key indicators including maintained visual appearance, consistent chemical resistance performance, and absence of progressive deterioration or damage accumulation. Surfaces should retain their original color and finish without developing permanent stains, scratches, or other defects that compromise functionality. Performance testing, such as chemical resistance spot tests or surface hardness measurements, should show consistent results over time. Documentation of maintenance activities and their outcomes provides objective data for evaluating program effectiveness and identifying areas for improvement. Regular feedback from facility users regarding surface performance and appearance also provides valuable insights into maintenance program success.