Modern laboratory and industrial environments demand surfaces that can withstand extreme conditions while maintaining functionality and safety. Among the various material options available, phenolic countertops have emerged as a leading choice for facilities requiring superior chemical resistance, durability, and performance. These specialized surfaces combine advanced resin technology with high-pressure laminate construction to deliver exceptional resistance to corrosive substances, thermal shock, and mechanical stress.

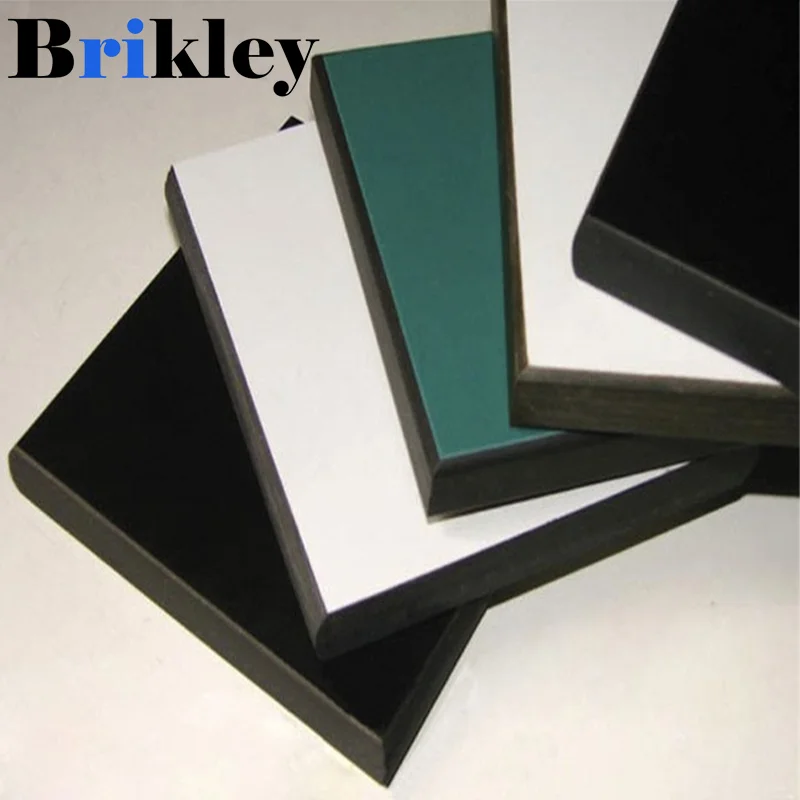

The unique manufacturing process of phenolic resin countertops involves multiple layers of kraft paper impregnated with phenolic resin, compressed under high temperature and pressure to create a homogeneous, non-porous surface. This construction method results in a material that outperforms traditional laminate surfaces in virtually every measurable category, making it an ideal choice for demanding applications across multiple industries.

Understanding which applications benefit most from phenolic countertop installation requires examining the specific performance characteristics that set these surfaces apart from conventional alternatives. From research laboratories to food processing facilities, the versatility and reliability of phenolic surfaces make them indispensable in environments where surface integrity directly impacts operational success and safety compliance.

Laboratory and Research Applications

Chemical Research Facilities

Chemical research laboratories represent perhaps the most demanding environment for any countertop material, requiring surfaces that can withstand exposure to aggressive acids, bases, solvents, and reactive compounds. A phenolic countertop excels in these conditions due to its exceptional chemical resistance properties, maintaining structural integrity even when exposed to concentrated sulfuric acid, hydrochloric acid, and various organic solvents that would quickly damage other materials.

The non-porous surface of phenolic resin prevents chemical absorption and contamination, ensuring that previous experiments do not interfere with subsequent research activities. This characteristic proves particularly valuable in analytical chemistry laboratories where trace contamination can compromise results and invalidate expensive research projects. The ease of decontamination also reduces downtime between experiments and minimizes the risk of cross-contamination between different research projects.

Additionally, the thermal resistance of phenolic countertops allows researchers to place hot glassware and equipment directly on the surface without causing damage or discoloration. This feature eliminates the need for protective mats or trivets, streamlining laboratory workflows and reducing the potential for accidents or spills that could occur when transferring hot materials to protective surfaces.

Biological and Medical Laboratories

Biological research laboratories and medical testing facilities require surfaces that can be thoroughly sterilized without degradation while maintaining resistance to biological stains and disinfectants. Phenolic countertops meet these requirements through their non-porous construction and resistance to bleach solutions, quaternary ammonium compounds, and other common laboratory disinfectants used in biosafety protocols.

The smooth, seamless surface of phenolic resin eliminates microscopic crevices where bacteria, viruses, or other contaminants might harbor, making thorough cleaning and sterilization more effective. This characteristic proves essential in clinical laboratories processing patient samples, where contamination control directly impacts diagnostic accuracy and patient safety outcomes.

Furthermore, the stain resistance of phenolic surfaces prevents the permanent discoloration that often occurs from biological specimens, reagents, and indicator solutions. This maintains the professional appearance of the laboratory while ensuring that surface discoloration does not interfere with visual assessments or quality control procedures that rely on accurate color perception.

Industrial Manufacturing Applications

Food Processing and Manufacturing

Food processing facilities face stringent hygiene requirements while dealing with acidic products, cleaning chemicals, and temperature variations that challenge conventional surface materials. Phenolic countertops provide an ideal solution for food preparation areas, quality control laboratories, and processing line support surfaces where contamination prevention and easy cleaning are paramount concerns.

The FDA-compliant nature of many phenolic formulations makes them suitable for direct food contact applications, while their resistance to organic acids from fruits, vegetables, and fermentation processes ensures long-term durability. The non-absorbent surface prevents the growth of bacteria and mold that could compromise food safety, while the smooth finish facilitates thorough cleaning with approved sanitizers and disinfectants.

Temperature resistance allows food processing operations to place hot containers and equipment on phenolic surfaces without damage, while the material's resistance to impact and cutting makes it suitable for preparation areas where knives and heavy equipment are regularly used. This combination of properties reduces maintenance requirements and extends surface life in high-traffic food production environments.

Pharmaceutical Manufacturing

Pharmaceutical manufacturing requires surfaces that meet strict regulatory standards for cleanliness, chemical resistance, and contamination prevention. Phenolic countertops excel in these applications due to their ability to withstand aggressive cleaning protocols involving strong solvents, acids, and sterilizing agents used in pharmaceutical production and quality control processes.

The validation-friendly properties of phenolic surfaces simplify compliance with FDA and other regulatory requirements for pharmaceutical manufacturing environments. The consistent, non-shedding surface eliminates particulate contamination concerns, while the chemical resistance ensures that cleaning and sterilization procedures do not degrade the surface or create potential contamination sources over time.

Clean room applications particularly benefit from phenolic countertops because the material does not outgas volatile compounds that could contaminate sensitive pharmaceutical products. The electrostatic discharge properties can also be controlled through appropriate formulations, making phenolic surfaces suitable for areas where static electricity control is essential for product integrity and worker safety.

Educational Institution Applications

University Chemistry Departments

University chemistry laboratories require durable surfaces capable of withstanding student use while maintaining safety standards for educational experiments involving various chemicals and equipment. Phenolic countertops provide the durability needed for high-traffic educational environments while offering the chemical resistance necessary for safe laboratory instruction and undergraduate research activities.

The forgiving nature of phenolic surfaces helps prevent minor accidents from becoming major safety incidents, as spills and splashes can be quickly cleaned without causing permanent damage or creating safety hazards. This characteristic proves particularly valuable in teaching laboratories where students are learning proper laboratory techniques and may not yet have developed the precision of experienced researchers.

Cost-effectiveness over the long term makes phenolic countertops an attractive choice for educational institutions with limited budgets, as the durability and low maintenance requirements reduce replacement and refinishing costs compared to less robust surface materials. The professional appearance also helps create an appropriate learning environment that mirrors real-world laboratory settings students will encounter in their careers.

High School Science Programs

Secondary education science programs benefit from phenolic countertops through enhanced safety and durability in student laboratory settings. The chemical resistance protects against common laboratory accidents while the impact resistance withstands the more robust use patterns typical in high school environments where supervision levels may be lower than in professional laboratories.

The easy maintenance of phenolic surfaces allows school custodial staff to maintain laboratory cleanliness without specialized training or expensive cleaning products. This simplifies facility management while ensuring that science classrooms remain safe and functional for multiple classes throughout the school day and academic year.

Heat resistance proves particularly valuable in high school laboratories where students may not yet have developed proper hot glassware handling techniques, as minor contact with hot equipment will not damage the surface or create safety hazards that could lead to injuries or liability concerns for the educational institution.

Healthcare and Medical Applications

Hospital Laboratory Services

Hospital laboratories processing patient samples require surfaces that can be thoroughly disinfected between samples while maintaining resistance to biological materials, chemical reagents, and sterilizing agents. Phenolic countertops meet these demanding requirements through their non-porous construction and broad chemical resistance that encompasses both biological materials and the harsh disinfectants used in healthcare settings.

The ability to withstand repeated sterilization cycles without degradation makes phenolic surfaces ideal for pathology laboratories, blood banks, and other medical testing facilities where contamination control directly impacts patient care quality. The smooth surface facilitates thorough cleaning protocols required for infection prevention while maintaining structural integrity under intensive use conditions.

Stain resistance prevents the accumulation of discoloration from biological specimens that could interfere with visual assessments or create concerns about surface cleanliness. This maintains professional standards while ensuring that surface appearance does not compromise the confidence of patients, staff, or regulatory inspectors in the facility's cleanliness and safety protocols.

Dental Laboratory Applications

Dental laboratories require work surfaces that can withstand exposure to dental materials, solvents, and cleaning agents while providing a stable platform for precision work. Phenolic countertops offer the chemical resistance needed for dental laboratory applications while providing the smooth, stable surface required for detailed prosthetic and orthodontic work that demands high precision and quality standards.

The dimensional stability of phenolic materials ensures that work surfaces remain flat and true over time, preventing warping or movement that could affect the precision of dental appliances and prosthetics. This stability proves essential for applications involving impression materials, casting procedures, and finishing operations that require consistent surface geometry for optimal results.

Easy cleaning and sterilization capabilities allow dental laboratories to maintain the hygiene standards required for medical devices while simplifying workflow processes. The resistance to dental materials and solvents prevents surface damage that could create contamination risks or require premature replacement of expensive laboratory furniture and equipment.

FAQ

How does phenolic countertop performance compare to epoxy resin surfaces in laboratory applications?

Phenolic countertops generally offer superior chemical resistance and durability compared to epoxy resin surfaces, particularly when exposed to strong acids, bases, and organic solvents. While epoxy surfaces may be more cost-effective initially, phenolic materials provide better long-term value through reduced maintenance requirements and extended service life. Phenolic surfaces also resist thermal shock better than most epoxy formulations, making them more suitable for applications involving temperature variations or hot equipment placement.

What maintenance procedures are recommended for phenolic countertops in high-use laboratory environments?

Regular cleaning with appropriate laboratory detergents and disinfectants maintains optimal performance of phenolic countertops without requiring special procedures or expensive cleaning products. Daily cleaning with mild alkaline cleaners removes most contamination, while periodic deep cleaning with stronger solvents can address stubborn residues. Avoid abrasive cleaners or scouring pads that could scratch the surface, and inspect regularly for any signs of damage that might compromise chemical resistance or hygiene properties.

Can phenolic countertops be repaired if damaged, or do they require complete replacement?

Minor surface damage to phenolic countertops can often be repaired through professional restoration techniques including sanding and refinishing, though the feasibility depends on the extent and location of the damage. Deep cuts, burns, or chemical etching may require section replacement or complete countertop replacement depending on the severity. The homogeneous construction of phenolic materials allows for more effective repairs than laminated surfaces, though prevention through proper use remains the most cost-effective approach to surface maintenance.

Are there specific phenolic formulations recommended for different industrial applications?

Different phenolic formulations are optimized for specific applications, with variations in chemical resistance, thermal properties, and surface characteristics. Laboratory-grade phenolic countertops typically offer maximum chemical resistance for research applications, while food-service formulations prioritize FDA compliance and stain resistance. Industrial applications may utilize formulations with enhanced impact resistance or specific color requirements. Consulting with manufacturers ensures selection of the appropriate phenolic formulation for specific operational requirements and performance expectations.

Table of Contents

- Laboratory and Research Applications

- Industrial Manufacturing Applications

- Educational Institution Applications

- Healthcare and Medical Applications

-

FAQ

- How does phenolic countertop performance compare to epoxy resin surfaces in laboratory applications?

- What maintenance procedures are recommended for phenolic countertops in high-use laboratory environments?

- Can phenolic countertops be repaired if damaged, or do they require complete replacement?

- Are there specific phenolic formulations recommended for different industrial applications?