Modern storage solutions require exceptional durability, especially in demanding environments like gyms, schools, and industrial facilities. A phenolic locker represents the pinnacle of advanced storage technology, combining high-pressure laminate construction with superior resistance properties. These innovative storage units have revolutionized how facilities approach long-term storage needs, offering unmatched performance in challenging conditions. Understanding the key features that make these lockers exceptionally durable helps facility managers make informed decisions about their storage infrastructure investments.

Advanced Material Construction and Engineering

High-Pressure Laminate Technology

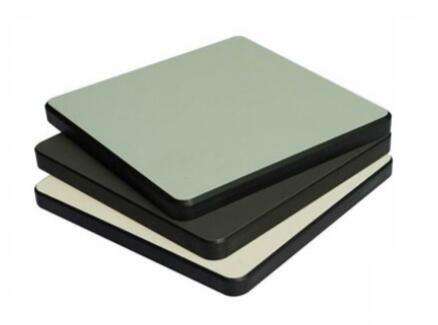

The foundation of phenolic locker durability lies in its sophisticated material composition. High-pressure laminate (HPL) technology creates an incredibly dense and resilient surface through a specialized manufacturing process that combines multiple layers of kraft paper with phenolic resin. This process involves subjecting the materials to extreme pressure and temperature, resulting in a homogeneous core that exhibits exceptional strength characteristics. The molecular bonding achieved during this process creates a material that surpasses traditional metal and wood alternatives in both durability and longevity.

The laminate structure incorporates decorative surface layers that are permanently fused to the core material, eliminating the risk of delamination or surface failure common in other locker types. This integrated approach ensures that the aesthetic appeal remains intact throughout the locker's operational lifetime. The manufacturing precision required for HPL production guarantees consistent quality across all components, from door panels to internal shelving systems.

Moisture Resistance Properties

Moisture management represents a critical challenge in storage environments, particularly in facilities with high humidity levels or frequent exposure to water. The phenolic resin system inherently repels moisture, creating a non-porous surface that prevents water absorption and subsequent structural degradation. This characteristic proves invaluable in pool areas, locker rooms, and outdoor installations where traditional materials would quickly deteriorate under constant moisture exposure.

The sealed edge construction technique used in quality phenolic lockers ensures that moisture cannot penetrate through joints or connections. Advanced edge-sealing compounds create watertight barriers that maintain the integrity of the internal structure, preventing the swelling, warping, and rot that plague wooden alternatives. This comprehensive moisture protection extends the operational life significantly while reducing maintenance requirements and replacement costs.

Chemical and Impact Resistance Capabilities

Chemical Compatibility and Cleaning Protocols

The chemical resistance of a phenolic locker enables the use of powerful disinfectants and cleaning agents without causing surface damage or degradation. This capability has become increasingly important in healthcare facilities, schools, and public spaces where rigorous sanitization protocols are essential. The non-reactive surface maintains its appearance and structural integrity even under frequent exposure to harsh cleaning chemicals, including bleach-based solutions and industrial-grade disinfectants.

Regular maintenance becomes simplified due to the chemical compatibility, allowing facility staff to implement comprehensive cleaning schedules without concerns about material compatibility. The smooth, non-porous surface prevents the accumulation of bacteria and contaminants, supporting improved hygiene standards while reducing the time and effort required for thorough cleaning. This feature translates into significant operational savings over the locker's lifetime.

Impact Resistance and Vandalism Protection

High-traffic environments subject storage solutions to considerable physical stress, making impact resistance a crucial durability factor. Phenolic materials demonstrate exceptional resistance to dents, scratches, and structural damage from impacts that would compromise metal or wood alternatives. The dense core structure distributes impact forces across a larger area, preventing localized damage that could lead to structural failure or aesthetic degradation.

The inherent toughness of phenolic construction provides natural vandalism resistance, deterring damage from deliberate abuse while maintaining structural integrity under normal operational stresses. This characteristic proves particularly valuable in schools, recreational facilities, and public spaces where equipment durability directly impacts operational costs and user satisfaction. The material's ability to maintain its appearance despite heavy use ensures a professional environment throughout the locker's service life.

Fire Safety and Environmental Performance

Fire Resistance Characteristics

Fire safety considerations play an increasingly important role in facility design and equipment selection. Phenolic materials naturally exhibit excellent fire resistance properties, with many formulations achieving Class A fire ratings without additional treatments or coatings. The resin system creates a char layer when exposed to flame, which actually helps protect the underlying structure and limits fire spread. This self-extinguishing characteristic provides valuable time for evacuation and fire suppression activities.

The low smoke generation and reduced toxic gas emission during fire exposure contribute to safer evacuation conditions compared to many synthetic alternatives. These safety characteristics often allow phenolic lockers to meet or exceed building code requirements without additional fire-retardant treatments, simplifying installation and reducing long-term maintenance concerns. The inherent fire resistance maintains effectiveness throughout the product's lifetime, unlike applied coatings that may degrade over time.

Environmental Sustainability and Indoor Air Quality

Modern phenolic formulations prioritize environmental responsibility through reduced volatile organic compound (VOC) emissions and sustainable manufacturing practices. The low-emission characteristics contribute to improved indoor air quality, supporting healthier environments for users while meeting increasingly stringent environmental regulations. Many phenolic products achieve GREENGUARD certification, confirming their suitability for sensitive environments including schools and healthcare facilities.

The longevity of phenolic construction reduces environmental impact through decreased replacement frequency and lower lifetime resource consumption. The material's recyclability at end-of-life supports circular economy principles, while the manufacturing process increasingly incorporates recycled content and renewable energy sources. These environmental benefits align with corporate sustainability goals while delivering superior performance characteristics.

Locking Mechanisms and Security Features

Electronic Lock Integration

Modern phenolic locker systems incorporate advanced electronic locking mechanisms that provide enhanced security while improving user convenience. Digital combination locks eliminate the need for physical keys or mechanical combinations, reducing administrative overhead while providing audit trails for access control. The electronic systems can integrate with facility management software, enabling remote monitoring and control capabilities that enhance operational efficiency.

Battery-powered electronic locks maintain functionality during power outages while providing low-maintenance operation over extended periods. The programmable nature of electronic systems allows for temporary access codes, master override capabilities, and user-specific access patterns that support diverse operational requirements. Integration with card readers or biometric systems further enhances security while streamlining user access procedures.

Mechanical Lock Reliability

Traditional mechanical locking systems continue to offer advantages in certain applications, particularly where electronic systems may be impractical or unnecessary. High-quality mechanical locks designed specifically for phenolic applications provide reliable operation over many years while requiring minimal maintenance. The precision manufacturing standards applied to mechanical components ensure smooth operation and long-term durability even under heavy use conditions.

The combination of robust mechanical locks with phenolic construction creates a security system that resists both forced entry attempts and environmental degradation. Stainless steel components resist corrosion while maintaining precise tolerances necessary for reliable operation. This mechanical reliability proves particularly valuable in outdoor installations or environments where electronic systems might be vulnerable to environmental conditions.

Installation and Maintenance Advantages

Modular Design and Installation Flexibility

The modular nature of phenolic locker systems facilitates flexible installation configurations that adapt to diverse space requirements and architectural constraints. Standardized components enable efficient assembly while allowing customization for specific applications. The lightweight nature of phenolic materials compared to metal alternatives reduces structural loading requirements while simplifying handling during installation and reconfiguration projects.

Pre-drilled mounting points and standardized hardware systems streamline installation processes, reducing labor costs and project timelines. The dimensional stability of phenolic materials ensures consistent fit and finish while eliminating the need for field adjustments common with other materials. This installation efficiency translates into reduced project costs and faster facility commissioning timelines.

Long-term Maintenance Requirements

The low-maintenance characteristics of phenolic construction significantly reduce operational costs over the locker's service life. Regular cleaning with standard facility maintenance procedures maintains both appearance and functionality without specialized treatments or replacement components. The non-porous surface prevents the accumulation of contaminants that could require intensive cleaning or refinishing procedures.

Component replacement, when necessary, can often be accomplished without replacing entire locker units due to the modular construction approach. Individual doors, shelves, or hardware components can be serviced independently, minimizing disruption to facility operations while controlling maintenance costs. The availability of replacement parts throughout the product's lifetime ensures continued functionality and appearance standards.

FAQ

How long does a phenolic locker typically last in high-use environments?

Phenolic lockers are designed for extended service life, typically lasting 15-20 years or more in high-use environments such as schools, gyms, and recreational facilities. The actual lifespan depends on usage patterns, maintenance practices, and environmental conditions, but the inherent durability of HPL construction ensures reliable performance throughout this extended period. Many installations continue functioning effectively beyond their expected service life with minimal maintenance requirements.

Can phenolic lockers withstand outdoor installation conditions?

Yes, phenolic lockers are well-suited for outdoor installations due to their excellent weather resistance properties. The non-porous surface resists moisture penetration, while UV-stable formulations prevent color fading and surface degradation from sun exposure. Temperature cycling, humidity variations, and precipitation have minimal impact on structural integrity or appearance, making phenolic construction ideal for outdoor recreational facilities, pool areas, and covered outdoor spaces.

What cleaning products are safe to use on phenolic locker surfaces?

Phenolic surfaces can safely withstand most commercial cleaning products, including bleach-based disinfectants, ammonia-based cleaners, and industrial-strength degreasers. The chemical resistance of the material allows for aggressive sanitization protocols without surface damage or degradation. However, abrasive cleaners should be avoided to maintain surface finish, and manufacturers typically provide specific cleaning guidelines to ensure optimal appearance retention throughout the service life.

Are phenolic lockers more expensive than traditional metal alternatives?

While phenolic lockers typically have higher initial costs compared to basic metal alternatives, the total cost of ownership often favors phenolic construction due to reduced maintenance requirements, longer service life, and superior performance characteristics. The elimination of rust, dent repair, and refinishing costs, combined with improved durability and appearance retention, generally provides better long-term value. Additionally, the enhanced user experience and facility aesthetics can justify the premium investment for many applications.