Modern laboratory and kitchen environments demand surfaces that can withstand the rigors of daily use while maintaining exceptional performance standards. Among the various materials available, phenolic countertop surfaces have emerged as the preferred choice for professionals who require durability, chemical resistance, and long-term reliability. These engineered surfaces combine advanced resin technology with practical functionality, making them indispensable in both scientific and culinary applications.

The unique properties of phenolic resin materials create surfaces that excel where traditional materials fail. Laboratory technicians and kitchen professionals alike appreciate the consistent performance these surfaces deliver under challenging conditions. Understanding the specific advantages of phenolic countertop installations helps explain their widespread adoption across diverse professional environments.

Chemical Resistance Properties

Acid and Base Resistance

Phenolic countertop surfaces demonstrate exceptional resistance to both acidic and basic solutions commonly encountered in laboratory settings. The cross-linked molecular structure of phenolic resin creates a barrier that prevents chemical penetration and surface degradation. This resistance extends to strong acids such as hydrochloric acid, sulfuric acid, and nitric acid, which would quickly damage conventional surface materials.

Laboratory applications frequently involve exposure to caustic solutions and alkaline compounds that can compromise surface integrity. Phenolic surfaces maintain their structural stability and appearance even after prolonged exposure to sodium hydroxide, potassium hydroxide, and ammonia solutions. This chemical inertness ensures that experimental results remain uncontaminated and that surface replacement costs are minimized over time.

Solvent Compatibility

Organic solvents present unique challenges for work surface materials, as they can cause swelling, discoloration, or complete dissolution of unsuitable materials. Phenolic countertop surfaces exhibit remarkable compatibility with common laboratory solvents including acetone, methanol, ethanol, and various hydrocarbon compounds. This compatibility extends to cleaning agents and sterilization solutions used in both laboratory and food preparation environments.

The dense molecular structure of phenolic resin prevents solvent penetration while maintaining surface smoothness and cleanability. Professional kitchens benefit from this property when using alcohol-based sanitizers and commercial cleaning products that might damage other surface materials. The consistent performance across different chemical exposures makes phenolic surfaces ideal for multi-purpose applications.

Durability and Longevity

Impact Resistance

Laboratory and kitchen environments subject work surfaces to frequent impacts from equipment, tools, and containers. Phenolic countertop materials excel in impact resistance due to their high-density construction and fiber reinforcement. The layered structure of these surfaces distributes impact forces effectively, preventing chipping, cracking, or permanent damage from dropped equipment.

Professional kitchens experience constant activity with heavy pots, cutting tools, and kitchen equipment creating potential impact scenarios. Phenolic surfaces absorb these impacts without showing visible damage or compromising structural integrity. This resilience translates to reduced maintenance costs and extended service life compared to materials like natural stone or ceramic tile that may crack under similar conditions.

Thermal Stability

Temperature fluctuations and heat exposure are common challenges in both laboratory and kitchen applications. Phenolic countertop surfaces maintain dimensional stability across wide temperature ranges, resisting warping, cracking, or delamination that can affect other materials. The thermal properties of phenolic resin allow these surfaces to withstand temperatures up to 180°C without structural compromise.

Kitchen applications benefit from this thermal stability when hot cookware or heated equipment contacts the surface. While direct flame contact should be avoided, phenolic surfaces can handle brief exposure to hot items without permanent damage. Laboratory applications involving heated equipment, autoclaves, or temperature-controlled experiments rely on this thermal stability for consistent performance.

Maintenance and Hygiene Benefits

Non-Porous Surface Structure

The manufacturing process of phenolic countertop materials creates an exceptionally non-porous surface that resists bacterial growth and contamination. This property proves crucial in laboratory settings where sterile conditions must be maintained and in commercial kitchens where food safety regulations require easily sanitized surfaces. The smooth, sealed surface prevents moisture and contaminant penetration that could compromise hygiene standards.

Traditional materials like wood or porous stone can harbor bacteria and organic matter in microscopic pores, creating potential health hazards. Phenolic surfaces eliminate these concerns through their inherently non-absorbent structure. Regular cleaning with standard disinfectants maintains optimal hygiene levels without requiring special treatments or sealers that other materials might need.

Easy Cleaning Protocols

Daily maintenance of phenolic countertop surfaces requires only basic cleaning procedures using common disinfectants and cleaning agents. The chemical resistance of these surfaces allows for aggressive cleaning protocols when necessary, including bleach solutions and quaternary ammonium compounds commonly used in professional environments. This cleaning compatibility reduces labor costs and ensures consistent sanitation standards.

Stubborn stains or residues that might permanently mark other materials can typically be removed from phenolic surfaces using appropriate solvents or mechanical cleaning methods. The surface hardness allows for light abrasive cleaning when needed without causing permanent damage or reducing the surface lifespan. This maintenance flexibility makes phenolic surfaces particularly valuable in high-use applications.

Design and Aesthetic Considerations

Color and Finish Options

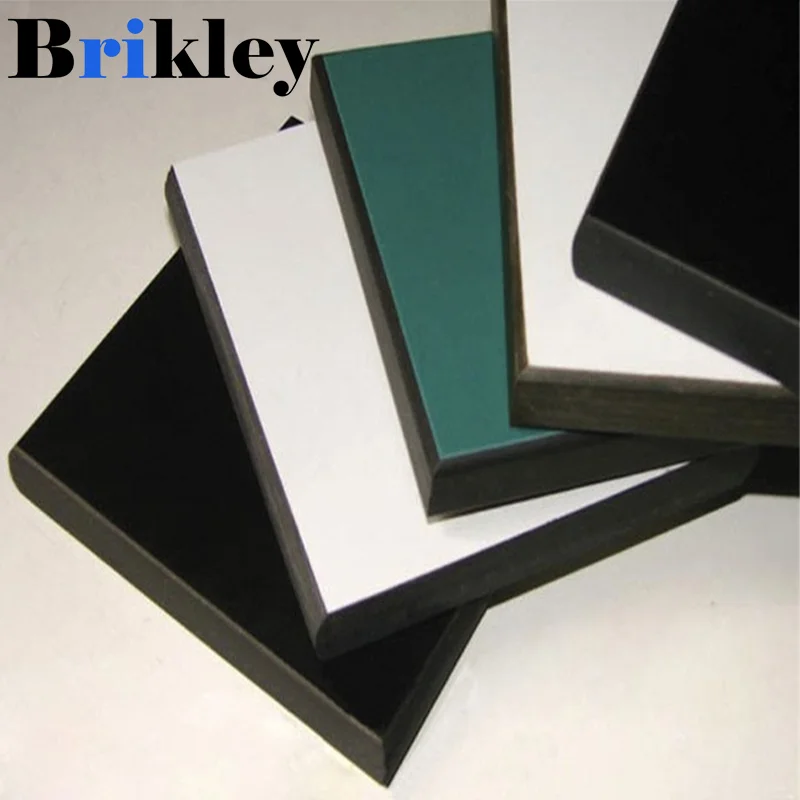

Modern phenolic countertop manufacturing offers extensive color and finish options to meet both functional and aesthetic requirements. Laboratory applications often prefer neutral colors like black, gray, or white that provide good contrast for sample visualization and reduce eye strain during extended work periods. Kitchen applications can choose from a broader palette that complements design themes while maintaining functionality.

Surface finishes range from matte to semi-gloss, allowing designers to balance aesthetic preferences with practical considerations like glare reduction and cleaning ease. Textured finishes can provide enhanced grip for safety in wet conditions, while smooth finishes maximize chemical resistance and cleanability. This versatility ensures that phenolic surfaces integrate well with existing design schemes.

Fabrication Flexibility

Phenolic countertop materials can be fabricated to precise specifications, accommodating complex laboratory layouts and custom kitchen designs. CNC machining capabilities allow for precise cutouts, edge profiles, and integrated features like drip edges or equipment mounting surfaces. This fabrication flexibility reduces installation complexity and ensures optimal fit in specialized applications.

Custom edge treatments, integrated sinks, and seamless installations are possible with phenolic materials, creating professional appearances that enhance the overall workspace aesthetic. The ability to create large, seamless surfaces reduces joint lines where contamination might accumulate, supporting both hygiene objectives and visual appeal in critical environments.

Cost-Effectiveness Analysis

Initial Investment Considerations

While phenolic countertop surfaces may require higher initial investment compared to basic materials, the long-term value proposition proves favorable for most professional applications. The extended service life, reduced maintenance requirements, and superior performance characteristics justify the upfront costs when evaluated over the total ownership period. Laboratory and kitchen operators often find that phenolic surfaces provide better return on investment than alternatives requiring frequent replacement or refinishing.

Facility managers appreciate the predictable performance characteristics of phenolic surfaces, which allow for accurate budgeting and maintenance planning. The consistent quality and durability reduce unexpected replacement costs and minimize disruption to critical operations. This financial predictability proves particularly valuable in institutional settings where budget constraints require careful resource allocation.

Operational Savings

Daily operational costs decrease significantly with phenolic countertop installations due to reduced cleaning time, lower maintenance requirements, and extended replacement intervals. Laboratory productivity increases when work surfaces require minimal preparation between experiments, while kitchen efficiency improves when surfaces can be quickly sanitized between food preparation tasks.

The chemical resistance of phenolic surfaces eliminates the need for protective measures that might be required with more vulnerable materials. Laboratory protocols can proceed without concerns about surface damage, while kitchen operations can use standard cleaning and sanitization procedures without fear of material degradation. These operational efficiencies contribute significantly to the overall value proposition of phenolic surfaces.

FAQ

How does phenolic countertop compare to stainless steel for laboratory use

Phenolic countertop surfaces offer several advantages over stainless steel including superior chemical resistance, quieter operation, and better thermal insulation properties. While stainless steel excels in extreme temperature applications, phenolic surfaces provide better resistance to acids and organic solvents commonly used in laboratory work. Additionally, phenolic surfaces eliminate the noise and vibration transmission associated with stainless steel, creating a more comfortable working environment.

Can phenolic countertops withstand commercial kitchen demands

Yes, phenolic countertop materials are well-suited for commercial kitchen applications due to their exceptional durability, chemical resistance, and hygienic properties. They can handle the constant activity, frequent cleaning, and temperature variations typical in professional food service environments. The non-porous surface meets health department requirements for food safety while providing the durability needed for heavy-duty commercial use.

What maintenance schedule is recommended for phenolic surfaces

Daily cleaning with standard disinfectants and periodic deep cleaning with appropriate solvents typically maintain phenolic countertop surfaces in optimal condition. Weekly inspection for damage or wear helps identify any issues early, while annual professional assessment ensures continued performance. The low-maintenance nature of phenolic surfaces requires significantly less attention than traditional materials, making them ideal for busy professional environments.

Are there any limitations to phenolic countertop applications

While phenolic countertop surfaces excel in most applications, they should not be exposed to direct flame or extreme temperatures above their rated limits. Certain exotic chemicals or prolonged exposure to strong oxidizing agents may affect surface appearance, though structural integrity typically remains intact. Professional consultation during material selection ensures that phenolic surfaces are appropriate for specific application requirements and chemical exposure profiles.